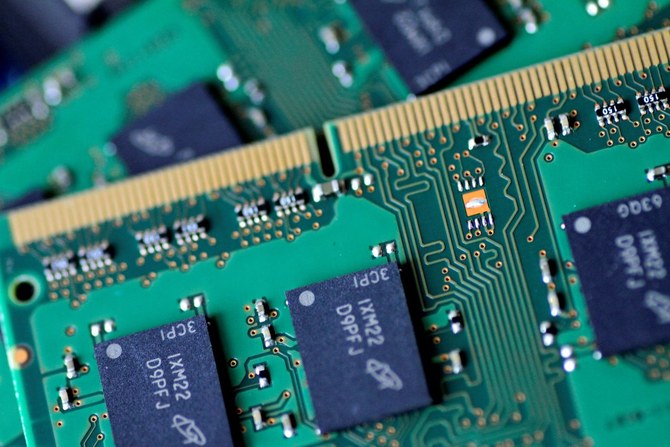

KUALA LUMPUR, Jan 10 — Moody’s Analytics expects the global semiconductor chip shortage to continue amid the Covid-19 Omicron surge, driven by multiple factors, but not worsening in 2022.

Senior economist at Moody’s Analytics Tim Uy said the Omicron surge should have a milder impact on the semiconductor chip supply chain.

He said a higher vaccination rate in major chip-producing countries worldwide compared with far lower numbers during the Delta spike in mid-2021, could soften the impact of Covid-19 Omicron on the semiconductor chip shortage.

“Things got particularly bad during the Delta surge in the middle of 2021, which hit Malaysia, Vietnam, Taiwan, Korea and Japan, key countries in the semiconductor supply chain. At that time, less than half of the population in those countries had received one dose of the Covid-19 vaccine, and only one-quarter was fully vaccinated.

“This meant the surge in cases led to significant halts in production, which caused a ripple through the rest of the chain — for example, factory closures in Malaysia weighed on Japanese production,” he said in a research note today.

Uy said the companies are also learning to mitigate supply-chain disruptions by building inventory and exploring alternative sourcing.

He added that the long-term constraints in expanding supply for the chip industry still apply, implying tightness in the year ahead.

“This trend towards building greater resilience is likely to continue well into 2022 as companies evolve with the changing times. Greater supply-chain resilience should help alleviate some of the disruptions that come to a head during difficult times.

“Market adjustments have not just come from the demand side; there have been supply-side adjustments as well,” he said.

Meanwhile, Uy said although Moody’s Analytics expects sales growth to moderate to 10 per cent this year, the secular movement towards increasingly digital world augers well for the industry.

As demand grows, it expects supply to slowly but steadily catching up.

“The major new foundries being built will only come online after 2023, so we expect capacity utilisation to exceed 80 per cent across all production lines through 2022. This means that lead times will be extended as supply remains tight,” he said.

Moody’s Analytics also expects governments around the world to support and fund efforts to increase domestic capacity in chip manufacturing, as well as supply-chain resilience more broadly.

— Bernama